Green Energy From Natural Resources

HOME | CERTIFICATIONS

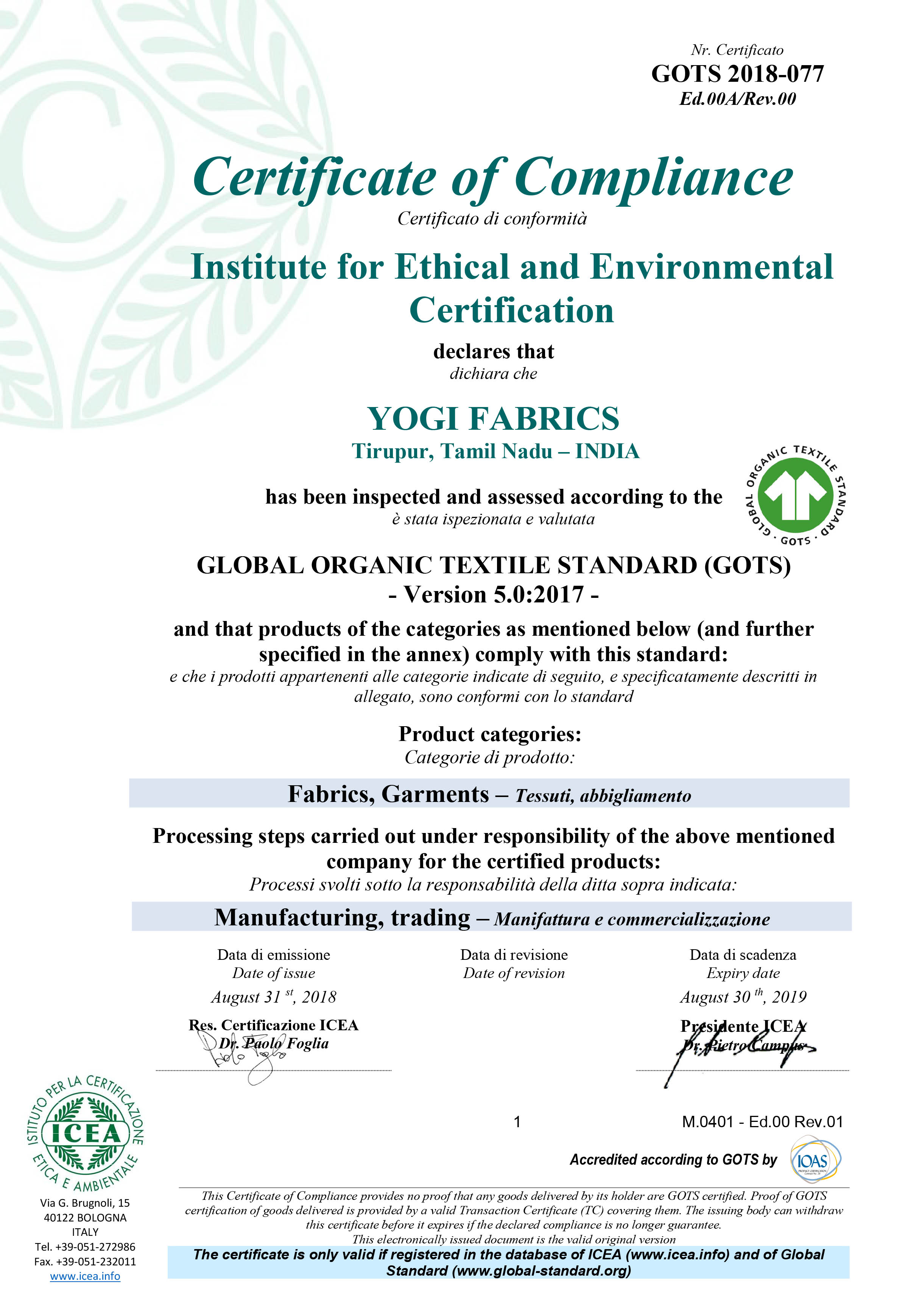

About GOTS

GOTS (Global Organic Textile Standard) is "recognised as the leading processing standard for textiles made from organic fibres worldwide. It defines high level environmental criteria along the entire supply chain of organic textiles and requires compliance with social criteria as well." All phases of organic fiber and fabric production must be inspected and certified according to GOTS' strict, uniform standards in order to obtain the certification label "organic".

FAIR TRADE

Fair trade is neither charity nor assistance; rather, it is a professional link between producer and buyer that is based on respect and fair business practice. The producer receives a fair price for his products which allows him to pay fair wages, thus giving workers the possibility of providing for their families with dignity.

From a fashion standpoint, Organic clothing now follows all the latest style trends. This means that there are now brands available which offer your favorite styles produced in organic cotton!

At Yogi Fabrics our goal is to meet the expectations of companies in quest of authenticity, coherence and quality in their production sourcing while ensuring the continued progress in the conditions of our workers lives.

We appeal to those who ask themselves: "Is it possible to change the world through everyday decisions? Does opting for natural and organic materials make a difference?"

In response to global environmental and economic issues, YOGI FABRICS works with companies worldwide to develop completely eco-friendly, socially-respectful lines of contemporary products. The universal concern that consumers are expressing in regards to social and environmental issues explains the success of this emerging market.

Besides the above, we also provide other benefits to the workers funding for worker's children's education. We believe that we are doing what we should to protect our future...

YOGI FABRICS currently certified by:

FLOCERT (FLO ID 40336), and Fair Trade-USA

ORGANIC PRODUCTS

The GOTS certification is a globally accepted way of providing credible assurance to consumers of the organic status of our textiles right from the harvesting of raw materials through environmentally and socially responsible manufacturing all the way to labelling.

DYEING

We use low-impact, fiber-reactive dyes for dyeing all our products. Our dyes are safe, GOTS certified and "low impact," which means that we use less water, less heat and produce less waste runoff than regular chemical dyeing processes.

Recent advances have created fiber-reactive dyes with colours that are brighter and richer than previously available, and they provide excellent colourfast properties on cotton. Fiber-reactive dyes have become the dye choice for many organic clothing manufacturers because they offer a diverse palette of vibrant colours. They contain no heavy metals or other known toxic substances, and they meet all European Union criteria for eco-friendly pigments.The dyeing process combines quality with technology through applications of advanced research at every level – from planning to production.

Multi-pronged use of technology and a trained pool of highly-qualified technicians help to meet all the required specifications.

COLORFAST the dyeing process conforms to international standards of colour-fastness like rubbing, perspiration, light and washing.

Research is focused on enhancing the standards of colour in the quality control laboratory.

PRINTING

Applying color patterns and designs to fabrics has been done since 5000 BC (Egyptian findings) and continues to be popular today for textiles of all sorts. It is, however, one of the most complex textile operations because of the many variables and the need for precision.

Printing is carried out after the dyeing or pre-treatment of the fabric. Dyes or pigments are applied locally to produce the artistic arrangement of various motifs in one or several colours. To ensure that the dyes stay separate from one another and remain fast to the fabric, a strong bonding is formed between dyes and fabric.

There are two main types of printing on fabrics, all-over rotary printing on both woven and knitted fabrics and screen printing.

Rotary printing is used when large quantities of fabric need to be printed with the same design (ex: sheets and other home linens, large runs of garment fabrics…). This method produces more unified, homogenous effects in the printing, as compared to screen printing. A large cylinder applies a dye paste to the fabric, which has been introduced between the engraved rollers, thus reproducing the desired design. This process is the most appealing for printing designer and fashion fabrics because of the high quality that can be achieved.

The importance of Organic Cotton

People are starting to know about the health benefits of buying organic food and using organic cleaning products, but what about organic materials in textile? If you are an animal lover, care about what goes on your body or are concerned with the welfare of others, take note: promoting organic fabrics has a major positive impact on your health and the health of our planet.

From a fashion standpoint, Organic clothing now follows all the latest style trends. This means that there are now brands available which offer your favorite styles produced in organic cotton!

However, the biggest benefit of organic cotton remains the environmental aspect: the crops are not treated with pesticides, insecticides, herbicides and Genetically Modified Organisms. These substances are harmful to farmers and workers, to us as consumers, and to entire wildlife eco-systems.

Organic cotton is grown in a way that uses methods and materials that lessen the impact on our environment. An important difference with organic growing systems is that they replenish and maintain soil fertility and build biologically diverse agriculture. Organic cotton uses far less water too.